1. Based on the calorie level of the customer, the system should internally map to one of the three size variants (Small, Medium, Large).

Answer:-

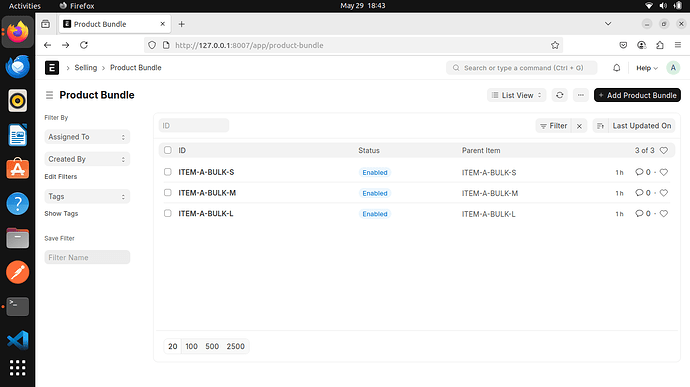

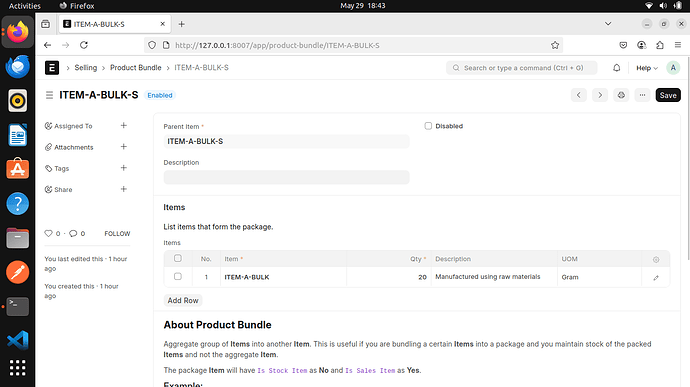

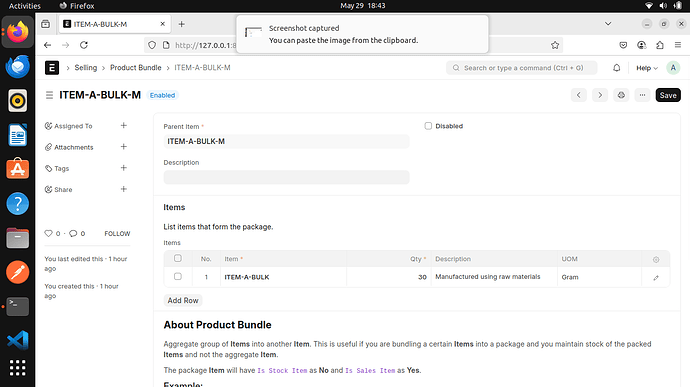

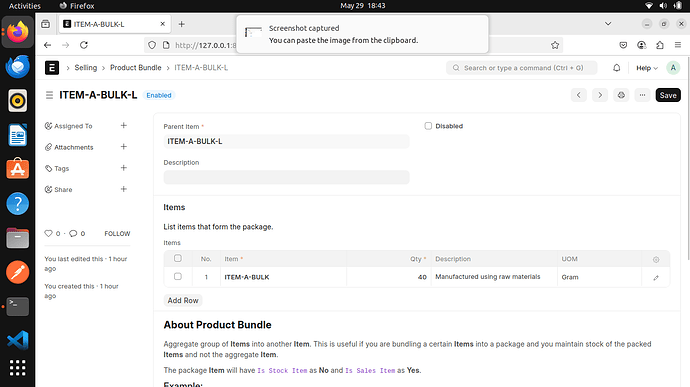

We’ve created three Product Bundles to represent the size variants:

- Item Bulk A - Small (20g)

- Item Bulk A - Medium (30g)

- Item Bulk A - Large (40g)

Each of these Product Bundles is internally linked to the main stock item Item Bulk A with the appropriate quantity.

To handle calorie-based mapping:

We can either use a custom intermediate Doctype (e.g., Customer Subscription or Calorie Profile) before Sales Order creation,

Or directly write a Server Script on the Sales Order that maps the calorie level to the correct Product Bundle and adds it to the SO.

Example logic for a Server Script:

calorie = doc.get("customer_calorie_preference")

if calorie:

if calorie < 250:

item_code = "Item Bulk A - Small" #service product bundle item 20g

elif 250 <= calorie < 350:

item_code = "Item Bulk A - Medium" #service product bundle item 30g

else:

item_code = "Item Bulk A - Large" #service product bundle item 40g

doc.items = []

doc.append("items", {

"item_code": item_code,

"qty": 1,

"uom": "Gram"

})

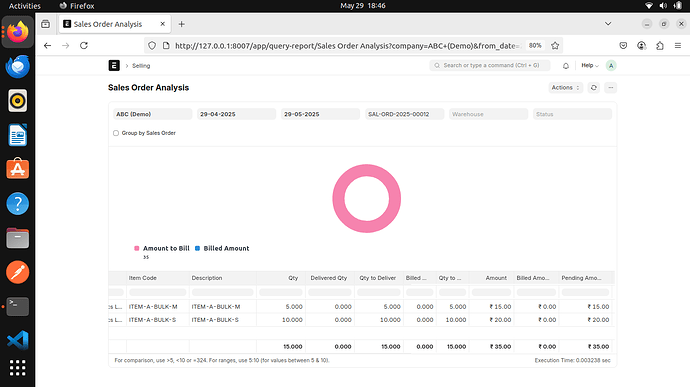

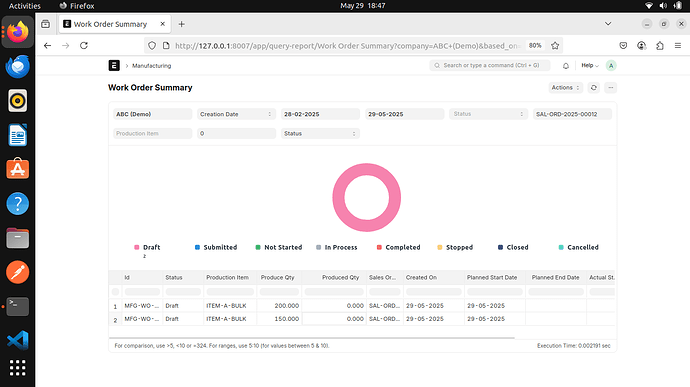

2. We should be able to calculate the total bulk quantity of Item A required by summing up all internal sizes (e.g., 10 smalls = 200g, 5 mediums = 150g, etc.).

Answer:-

We use Sales Orders (linked to the Product Bundles) to estimate the demand for each size.

Since each bundle links to a fixed quantity of Item Bulk A, we can use standard ERPNext reports (e.g., Sales Order Analysis or Work Order Summary) to sum total quantity of Item Bulk A required.

Example: 10 Small (20g) + 5 Medium (30g) → 200g + 150g = 350g of Item Bulk A to manufacture.

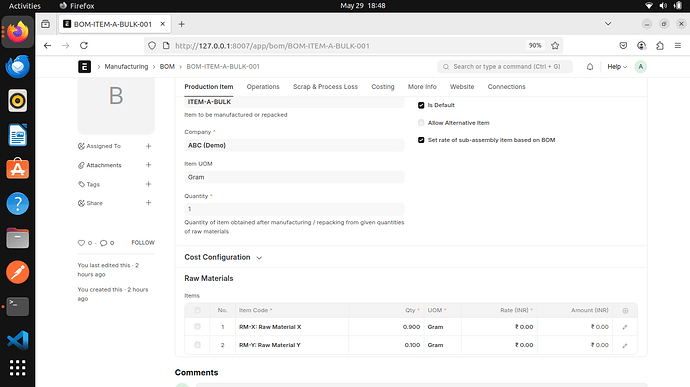

3. The bulk Item A is manufactured using raw materials X and Y via a Work Order.

Answer:- We can create a BOM for Item Bulk A, listing Raw Material X and Y as components. This BOM is used to create a Work Order and manufacture the bulk quantity based on the estimated demand.

4. After bulk production, we pack it into the required number of Small/Medium/Large units based on daily demand. ( should able to define the box quantities like a Product Bundle or something)

Answer:-

This depends on the business workflow:

a) Make to Order

-

Each Sales Order includes the correct Product Bundle (automatically selected using the calorie logic).

-

From the SO, we can generate Delivery Notes and Sales Invoices directly for the customer.

b) Make to Stock

-

We raise Material Requests based on daily packing requirements.

-

Then create Work Orders for converting bulk into required units (S/M/L).

-

This gives flexibility to pack as per batch demand.

ERPNext supports both workflows natively, depending on how you manage inventory and production planning.

5. Customer should only see Item A (no size info) on invoices, delivery, etc.

Answer:-

Although internally we track Small/Medium/Large, customers should only see “Item A” on Sales Invoices and Delivery Notes.

To achieve this:

We customize the Print Format to display a generic item name (Item A) and hide internal size info.

This ensures the customer always sees a clean and simple product label.

NOTE: Since I don’t use item variants in my case—as it totally depends on whether they are required or not—I felt it became much more complex. So, I used product bundles instead.