We need little help. Let me explain you.

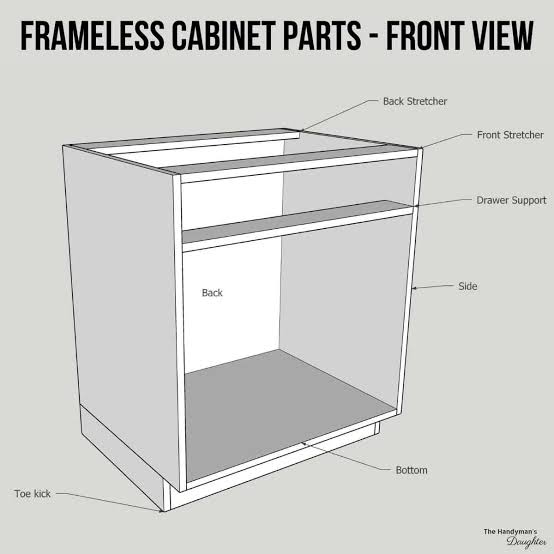

Recently, we are trying to migrate our ERP from Odoo to ERPNext. We are in green house accessories manufacturing. We making many of item which has semi finished goods (i.e intermediate item). These semi finished item needs to have stock so we have proper inventories as this item can be used to manufacture other items also. So we have made intermediate item with its BOM as we do in Oddo.

But we have issue with Material Request and Work Order. Let me explain process.

We have item called Clamp with is made from GI Sheet. GI Sheet has stock UoM as Kg and Clam has Nos. Between them there is 4 semi finished goods item we called as (GI Sheet Nos, BSH, SSH, PPP, PPE) and all has Nos as default UoM. 1 Sheet 49.060 Kg (its varied every time). So here are the BOMs.

GI Sheet (KG) - GI Sheet (Nos) – BHS – SSH – PPP – PPE - Clamp

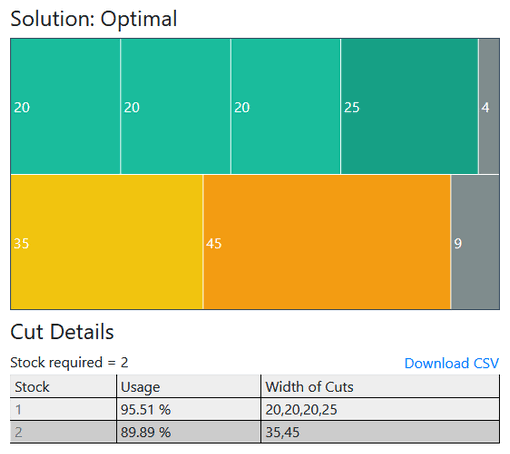

49.060Kg–1 sheet– 4 sheet cut (BHS)– 62 sheet cut (SSH) –1 piece (PPP) –1 piece (PPE) –1 (Clamp)

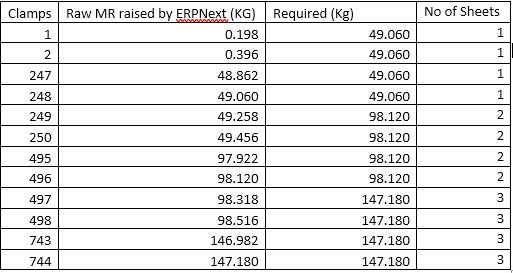

So here 1 sheet can produce total 248 Camps.

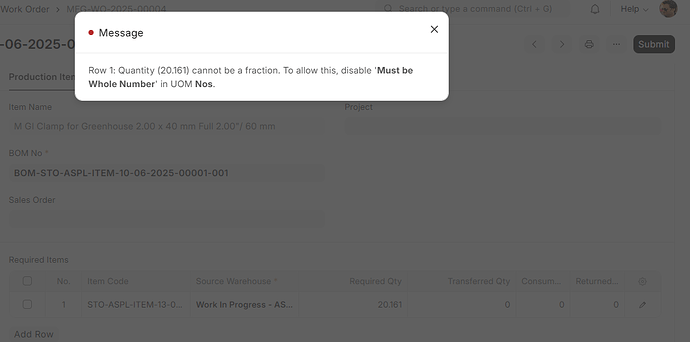

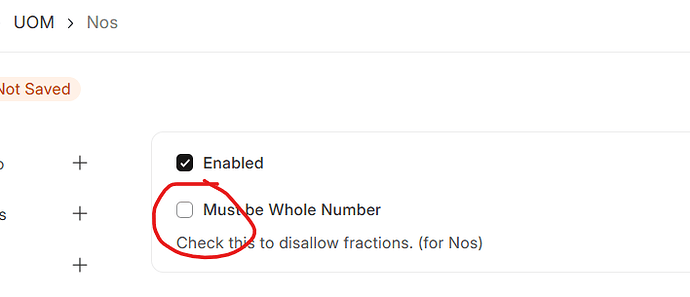

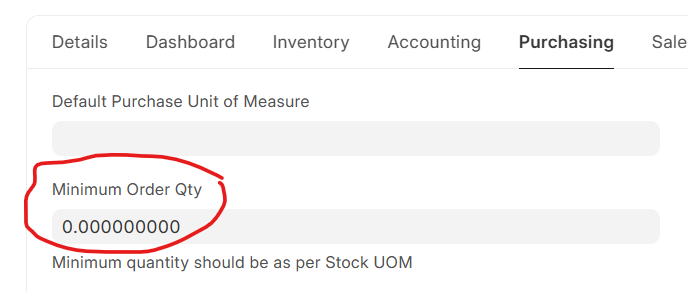

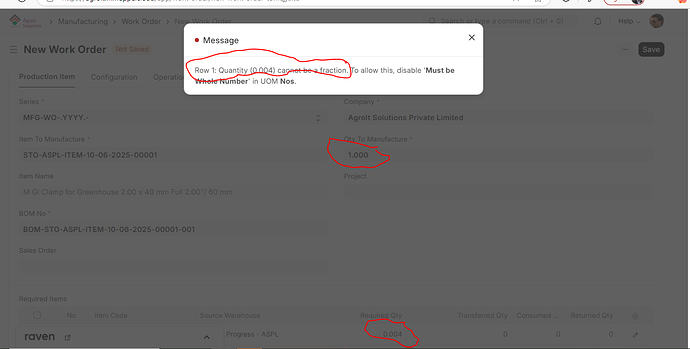

Now the problem is that if I raised MR/WO for 1 Clam then ERPNext will be raising the request of 0.198 Kg not full sheet i.e, it should be raised 49.060Kg. Here is the sample use cases:

Expected vs. actual behavior is attached.

So expected MR/WO should raised full sheet Kgs as we can not procure cutting GI sheet its need to be in full.

Could you help us how we can handle this scenario as we have many items which has this type of items.

Any help or insights would be greatly appreciated! Thanks.

Best regards,

Mayur Pansheriya