We have tried using templates and variants in ERPNext, but the process has become too complex due to the large number of SKUs and variations. Therefore, we need to customize the system to work more efficiently based on the following requirements:

- Adding a Subtable Inside the Item Definition:

When creating a new item, it should include a subtable with the following columns:

• Size: Shoe size (e.g., 40, 41, 42,…).

• Color: Shoe color (e.g., Black, Brown, White,…).

• Quantity per Carton: The number of pieces of each size and color in one carton.

• Barcode: A unique barcode for each size and color within the same item.

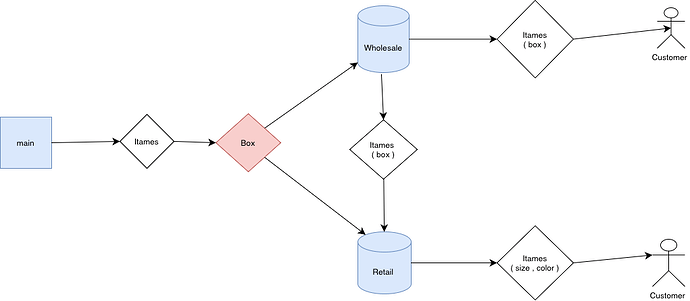

- Sales & Purchase Mechanism:

Retail Sales:

• Sales should be based on the sub-barcode registered in the table (linked to size and color).

• When scanning the barcode, the system should fetch the item and deduct the quantity from the corresponding size and color according to the scanned sub-barcode.

Wholesale Sales & Purchases:

•Sales and purchases should be based on cartons, where the quantity is entered in cartons during purchase or sale.

- Stock Balance Should Be Displayed in Both Cartons and Pieces

Stock Entry and Distribution Based on Carton Composition:

When purchasing cartons, the system should automatically distribute the quantity according to the predefined carton composition in the item’s subtable.

Practical Example:

Let’s say we have an item “Sports Shoe Model X” with the following carton composition:

Size Color Quantity per Carton

40 Black 2

41 Black 2

42 Black 2

40 White 2

41 White 2

42 White 2

• When purchasing 5 cartons of this item, the stock should be distributed as follows:

Total Cartons in Stock: 5 cartons.

Total Pieces Recorded in Stock:

Size 40 Black = 5 x 2 = 10 pieces.

Size 41 Black = 5 x 2 = 10 pieces.

Size 42 Black = 5 x 2 = 10 pieces.

Size 40 White = 5 x 2 = 10 pieces.

Size 41 White = 5 x 2 = 10 pieces.

Size 42 White = 5 x 2 = 10 pieces.

Total Pieces in Stock = 60 pieces.

Stock Deduction During Sales Based on Unit Selection:

• Retail Sales: Sales should be based on the sub-barcode linked to size and color, and the quantity should be deducted in pieces.

• Wholesale Sales: Sales should be based on cartons, and the stock should be deducted in cartons.

- Customizing Stock Reports to Show Balance in Cartons and Pieces:

The Stock Balance Report should support two views:

-

Stock in Cartons per item.

-

Stock in Pieces per size and color.