Hello ErpNext team,

Is there any way to manage the coal mining plant process and stock management in ErpNext manufacturing?

Similarly, I am looking to manage the copper mining process in which we will get multiple products from a single raw material.

Thanks,

Krunal Jariwala

Hey @jariwalakrunal,

While theoretically possible, practically implementing this without some level of automation might be challenging.

It seems like your process operates on a continuous flow basis with a standard loss rate. For instance, you expect a 5% loss in concentration when processing 100 tons of Raw One, resulting in 95 tons of Concentration.

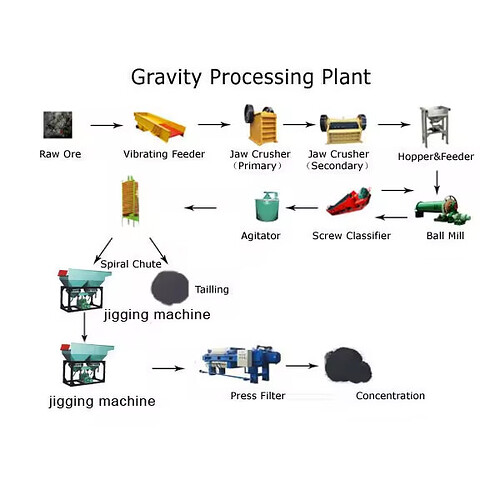

In ERPNext, you could theoretically model various stages such as the Vibration Feeder, Jaw Crushers, Ball Mill, etc., as workstations and operations running simultaneously. However, automation is crucial for closing all associated job cards when closing a work order.

Equally important is leveraging historical data to determine average production within specific timeframes, aiding in periodic work order scheduling.

Ideally, incorporating automation for continuous scaling at the end of the process, say after the ‘Press Filter’, would provide real-time data for production analysis.

Best wishes on your ERPNext journey! Do share your progress; it’d be fascinating to hear about your project.

Regarding Copper, the principle remains similar. Considering the scrap perspective might offer valuable insights and potentially resolve any bottlenecks in your process.