hi every one

one of my item is a custom print so

when i make a production order from sales order

first step is to make design and then printing

so do i have to make production order twice one for design and the other for printing or this two both in one production order ?

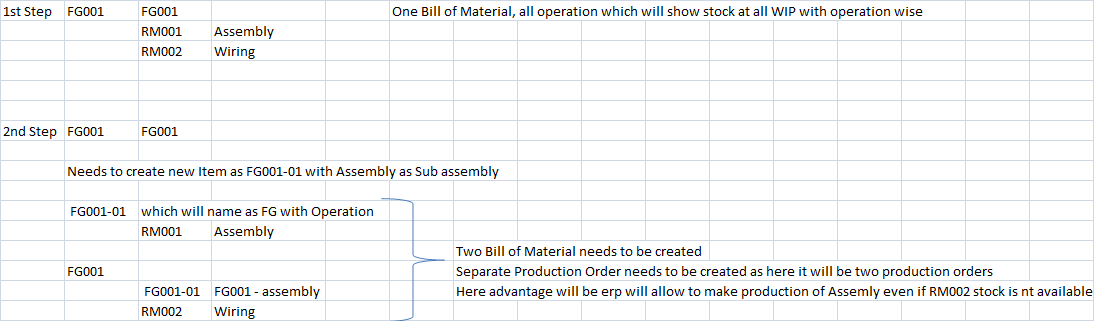

1st Step FG001 FG001 One Bill of Material, all operation which will show stock at all WIP with operation wise

RM001 Assembly

RM002 Wiring

RM001 Assembly

RM002 Wiring

2nd Step FG001 FG001

Needs to create new Item as FG001-01 with Assembly as Sub assembly

FG001-01 which will name as FG with Operation

RM001 Assembly

Two Bill of Material needs to be created

FG001 Separate Production Order needs to be created as here it will be two production orders

FG001-01 FG001 - assembly Here advantage will be erp will allow to make production of Assemly even if RM002 stock is nt available

RM002 Wiring