I have noticed the following with regards to Job Cards. I have tried searching the forum but have not found any satisfactory answers to these

- If I use multi level BOM, each job card shows full quantity of the main product even if the sub assemblies form a smaller part of the main product. For example,

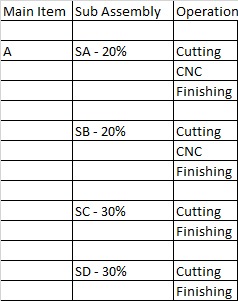

In the above case, if I use multi level BOM to make 100 units of main item, the Job cards that are created are 10 in number which is expected. However, each job card shows “quantity to manufacture” as 100 units, which is incorrect.

-

Secondly, while using multi level BOM, the Job Card nowhere shows the sub-assembly item code, name and quantity. It directly shows the main item code. This creates confusion and we can’t identify which Job card is related to which intermediate sub assembly. For example in the scenario mentioned in point 1, four job cards are created for operation ‘cutting’. However, on opening each of the job card, we are unable to identify which job card corresponds to which sub assembly.

-

While creating BOM, in each operation we mention some details about work to be carried out in the field “description”. However, this description is not pulled into Job Cards. So when the operator opens the Job card, he doesn’t know the details of the operation. All job cards of same operation look same without any details.

-

Can we do away with the job cards? Right now our set up is not ideal to track and update all the details regarding Job Cards. Is it possible that we work only with Work Order but still get an estimate of the time required for operations and the costing related to operations?