Dear all,

i have been studying ERPNext manufacture module, in my factory, we have assemble and injection shop floors, to implement ERPNEXT manufacture, if create job card, do i have to start and finish a operation by clicking every time?

i think we can manually put the time consumed, don’t have to get it by clicking start/finish button

@RoyHu is correct.

On V12 there was no time entry in the table. You had to either load it by hand or use the start/stop.

On V13, the table has pre-loaded the time that you have setup in the BOM. If you feel that time

is accurate then you can simply Complete the job-card or you can enter the time by hand or

use the star/stop.

I haven’t worked on V14. I should imagine it is the same as V13.

@willspenc Hello, it is exactly as you mentioned, thank you!

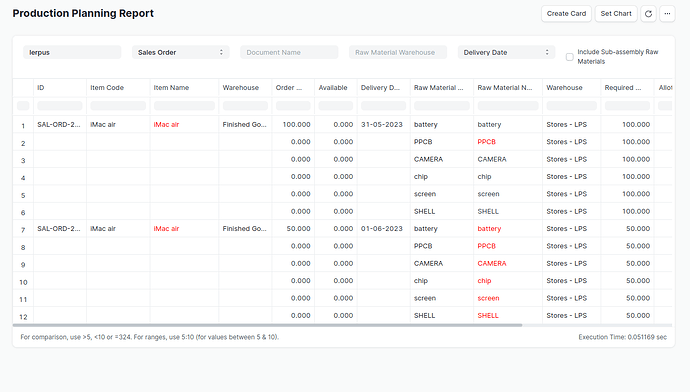

by the way, is there a report to show material status by selecting a date range? for instance, how many in the stock, how many occupied by which work order, how many in transit(confirmed PO),especially show production plan draft work order needs for material, this report is good for material preparation for various production plan

Hi @RoyHu

The Production Planning Report is a very nice report but I don’t think it gives all the stuff that

you have listed. Perhaps what you can do is, go and have a look at the code for the

Production Planning report and then you can perhaps use that as a starting point and maybe if you

add a bit of SQL coding and drop that into a custom (client side) report … you could perhaps

add the values you want ? That would require back-end access. Not sure if you have a self-hosted

setup or not …???

You mentioned “PO”. I assume that would be a customer PO so on the system it will be SO.

Maybe also look a the reports under “Selling”. There are some nice reports that is linked to SO.

@willspenc ,thank you very much for the guide. the PO i mean purchase order(confirmed PO which we consider as stock), this report is for a scenario, when i had prepared many production plans, not submitted yet, i want to know how much the material i need to purchase, too much PO would add high inventory risk, too little PO will cause material shortage. that is i want this report for. purchase the right QTY of material.

for a certain date range.

hi @RoyHu

My bad. I misinterpreted that part of your post ! And I understand your requirement.

I had a quick look at the tables in mariadb …

tabWork Order Item

item_code ; required_qty

tabPurchase Order Item

item_code ; qty

tabProduction Plan Item

item_code ; planned_qty

These are all child tables but one should be able to link that to the parent-doc to get

e.g. Production Plan nr.

Edit …

Actually just looked at tabBin…

there are colums such as

ordered_qty

planned_qty

projected_qty

reserved_qty_fr_production

reserved_qty_for_sub_contract

actual_qty

Hello willspenc,

thank you so much for the helps, sorry to bother you again,

in workstation, there is “Consumable Cost”, what does it mean? does it include the material consumed?

in the BOM, there is scrap items to setup, if i assembly 100 torchs, need 100 pieces of Lens,springs,etc. if i broke one piece of Len, then i need the raw material lens of 101, or i may broke one pieces of spring, that is unpredicable, how to setup the scrap items.

in the BOM, what is the process lost?

Hi @RoyHu

No problem.

No. Material consumed is under your “Item” table under “Materials” in your BOM

Consumable cost would be consumables that is used at a workstation like glue.

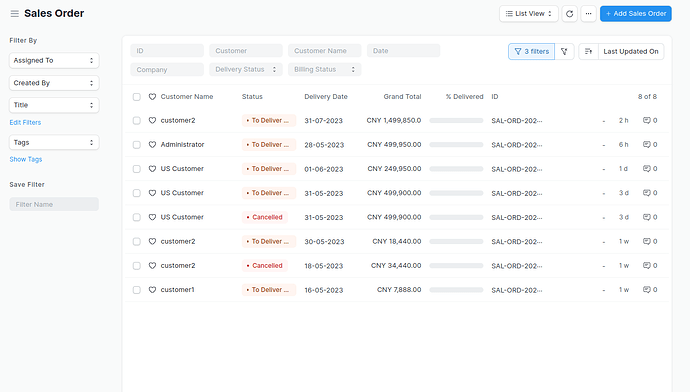

@willspenc, appreciate all the helps, i encountered a problem again today, could not solve it, i submitted a few sales orders, i only see two sales order in the production planning report(it should show 4 sales orders in the report), thank you!

@willspenc , i think i found where i got it wrong, it is in the item master setting. think you for all the helps you provide to me, think you for your time spending on me.

Hi @RoyHu

Also remember to set the field “Get Items from” correctly when you raise a production plan.

Hello @willspenc ,

got it. thank you!

Hello @willspenc ,

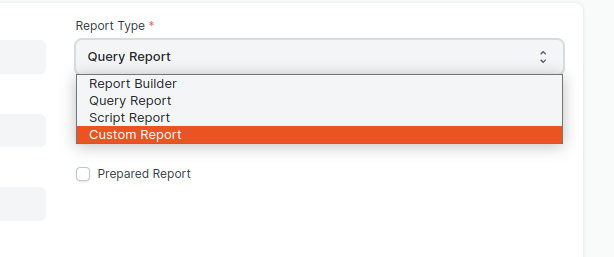

appreciate the helps you provided to me, i have been studying custom report these days following the guide you give to me above, the doctype should be production Plan to link for custom script, is it? then how to proceed with it, i know there is a lots to learn, i think i can get it through when i had a sample of doing custom report.

Dear @willspenc , the more i learn, then look back to your help here, i got a little bit confused here,

“drop that into a custom (client side) report”,is the report as the report in the screenshot?

Hi @RoyHu

Sorry for the late response.

Here then an example of a query report that I did.

Columns

Parent BOM, Parent BOM, Data

Item Code, Item Code, Link , Item

Item Name, Item Name, data

BOM No, BOM No, Link, BOM

Qty. Qty, Data

Warehouse, Warehouse, Link, warehouse

Lead Time Days, Lead Time Days, Int

Quotation Qty, quotation qty, Int

Sales Qty, Sales Qty, Int

SELECT

bi.parent as "Parent BOM:Link/Parent BOM:400",

bi.item_code as "Item Code:Link/Item Code:400",

bi.item_name as "Item Name:Data/Item Name:400",

bi.bom_no as "BOM No:Link/BOM No:400",

bn.actual_qty as "Qty:Data/Qty:400",

bn.warehouse as "Warehouse:Link/Warehouse:400",

i.lead_time_days as "Lead Time Days:Int/Lead Time Days:400",

qi.qty as "Quotation Qty:Int/Quotation Qty:400",

sii.qty as "Sales Qty:Int/Sales Qty:400"

FROM

`tabBOM` b

INNER JOIN `tabBOM Item` bi ON b.name=bi.parent

LEFT OUTER JOIN `tabBin` bn ON bi.item_code=bn.item_code

LEFT OUTER JOIN `tabItem` i ON bi.item_code=i.item_code

LEFT OUTER JOIN `tabQuotation Item` qi ON bi.item_code=qi.item_code

LEFT OUTER JOIN `tabSales Invoice Item` sii ON bi.item_code=sii.item_code

WHERE bi.parenttype='BOM' GROUP BY bi.item_code

Dear @willspenc ,

this is very nice of you, i never expect this would come, this is too much to ask. it is very helpful for me to extend my knowledge of frappe and erpnext.

here troubling you for a case, glue is not part of BOM, but if we don’t put glue in the BOM, during production, we need glue, but there is no glue prepared. cause downtime. is there a good solution better than putting glue in the BOM.

Dear @willspenc ,

hate to bothering you like this, i just completed a job card for 100 pieces FG, i put 1 piece of scrap FG in the scrap table in the job card, should be 99 FG left for the stock entry of manufacture, but the stock entry keep asking me to fill 100 pieces of FG to submit. and the 1 piece of scrap FG goes to the FG warehouse instead of scrap warehouse. did know where to set scrap item goes to scrap warehouse.

Good day @RoyHu

Why don’t you do a stock entry to transfer the one unit to scrap or to a “Faulty” warehouse?

I think the question to ask is, is that really scrap ?

When I read about scrap, I interpreted it in this way …

Your process uses 1mx3m wood. You require 1mx2.5m. So the 1mx0.5m is scrap. It is a known

piece of “offcut” and you define it as such in your item list.

So that goes into a scrap warehouse where you can now use these scrap pieces of wood in

another process.

Perhaps someone else on the group has another view-point ?

Perhaps you should ask these questions in new posts everytime so that the other users can

pick up that it is a new question and they can also comment.

Just my interpretation.