We are planning to transfer the items from Old Warehouse to New Warehouse and each item must have sticker name and location on it, to easily determine the list of items if there is a deliver or inventory. How to add the location for instance i want to check this item in the system and it show’s me the designated location of this products which is tally to physical that is located to Racks-A-01

Thanks

Hi,

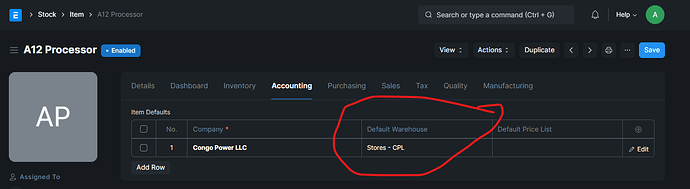

You can define the default warehouse for each item on the Item Master under Accounting Tab:

Thanks,

Divyesh Mangroliya

Now my question is where is the located in physical? for intance the manager ask you please check this item “A”? in warehouse Store - CPL?

Hi,

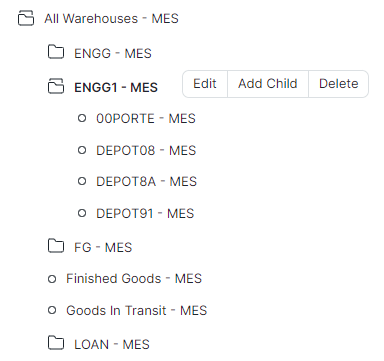

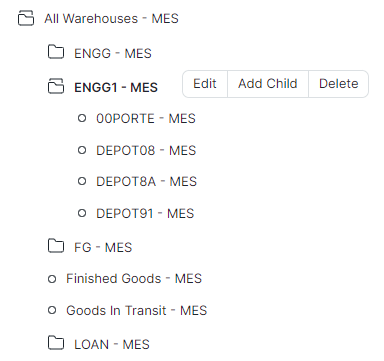

Warehouse is the Tree Structure.

For example Warehouse Store - CPL is the physical building and inside that building you have three Racks, Rack01, Rack02 and Rack03 and each Rack contains 5 Shelfs. You can follow the tree structure to create the same.

If you need more complex setup, you can use the Inventory Dimension also.

Please go through the Warehouse Manual : https://docs.erpnext.com/docs/v13/user/manual/en/stock/warehouse

Please go through the Manual for Inventory Dimension: https://docs.erpnext.com/docs/v13/user/manual/en/stock/inventory_dimensions

You can learn more about Inventory Management in ERPNext on Frappe School. Courses on Frappe School are Free of Charge.

Course Link for Inventory Management : Inventory Management

Thanks,

Divyesh Mangroliya

1 Like

thank you for the information.

I’ve been exploring the inventory system in ERPNext, specifically focusing on managing inventory across multiple storage locations (Racks, Bins, Etc). However, I’ve encountered some challenges and I’m wondering if I might be missing something in my approach.

Challenges with Multiple Warehouses: I’ve tried using a separate warehouse for each storage location, but I’m facing issues with the projected stock quantity in transactions like quotations and sales orders. Here’s what I’ve noticed:

- When creating a sales order, if I don’t specify the exact storage location (warehouse) right away, the system seems to reserve the quantity in a general warehouse.

- Subsequently, when I generate a quotation, it shows a negative Projected Qty and an Actual Qty of 0 for the default warehouse.

- However, if I select the correct storage warehouse instead of the default, the projected quantity doesn’t seem to display correctly.

Ideally, we’re looking to understand the total Actual and Projected Qty for an item across all warehouses, as our items can be stored in multiple bins.

Inventory Dimensions Issue: I also experimented with adding inventory dimensions but faced a limitation:

First I added a custom DOCTYPE called Storage Bin, The inventory dimensions is using this DOCTYPE as a reference document.

- For example, if I have 10 pcs in bin001 and receive another 5 pcs which I store in bin002 (noted in the purchase receipt), the stock balance appears to show all 15 pcs in bin002 only, rather than distributing them across both bins.

Could anyone please advise if there are steps or configurations I’m missing in these scenarios? Any insights or suggestions on how to effectively manage inventory across multiple storage locations would be greatly appreciated.

@Bas_de_Reus @gabby1981

Hi Guys! I understand creating a warehouse for each storage location is a tedious task and certainly it is not efficient at all. That is why the concept of Inventory Dimension is Introduced.

One more thing to be considered here is

There is no global inventory for any item, Whatever inventory values you get in any doctype have always a warehouse field with it and hence its corresponding Quantities. Be it Actual Quantity or Projected Quantity.