I am trying to use the Production Planning tool but it does not seem to be functioning the way I would have expected.

Here is the process I am trying to accomplish:

- Receive Sales Order for a final product (S3004)

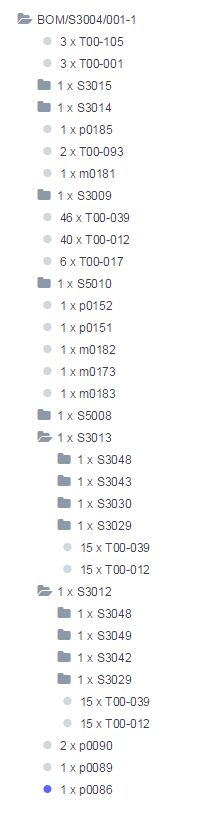

- Create Production Orders for the final product, plus all of the sub-assemblies that need to be manufactured. (S3009, S3012, S3013, S3014, S3015, S5008, S5010). Also, there are sub-assemblies required to produce S3012, S3012 for example have 4 other subassemblies).

- Create Material requests for all of the purchased parts.

Here is the sample BOM I’m working with:

For step #1, using the Selling->Sales Order has been easy to do.

For step #3, using the Production Planning tool, loading the sales order, Getting the items from the Sales Order, and selecting Use Multi-Level BOM creates all the material requests that I need.

The trouble happens with Step #2. Only one production order is created (for S3004). If my production team needs to look at a list of what there is to make, how would they know to make all the subassemblies first?

Thanks for any assistance!