I have an item (SAE-0113) that has a BOM. The BOM only has 2 parts in it

- CB1-0085

- CN3-0154

I have setup 3 warehouses

- Stock

- WIP-order1

- Finished Products

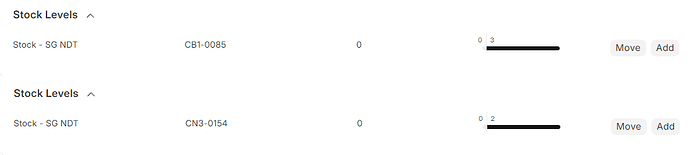

The stock level for the 2 parts are

- CB1-0085 = 3 available in warehouse Stock

- CN3-0154 = 2 available in warehouse Stock

I create a work order (WO#1) to manufacture 3x SAE-0113.

I configure the WIP warehouse as WIP-order-1 and the target warehouse as Finished Products.

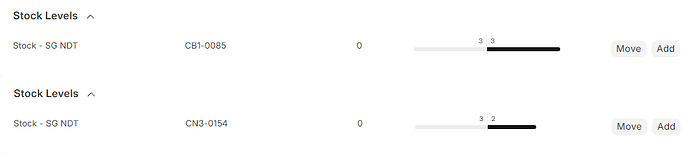

Once I submit my work order, I can see the Stock Level of the parts showing 3 as a reserved quantity.

Back to my work order, I create a pick list. I then get a message saying

1.0 units of Item [CN3-0154] is not available in any of the warehouses.

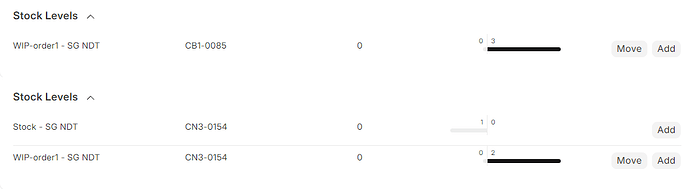

I then continue with my pick list for the items I have in stock. After saving my Pick List, I create a stock entry to move the items from Stock to WIP-order1.

If I check the Stock Levels again I see this

Here are my questions

-

Why is the reserved quantity for CN3-0154 applied to the Stock warehouse instead of the WIP-order1 warehouse?

-

Looking at the Stock Level for CN3-0154, how do I know where is the reservation coming from? (It shows 1 unit reserved but for what work order? what sales order?)

-

How do you make a material request from a work order considering that a partial material transfer has been done already? (I did a pick list but some items were not in stock)

-

How do you add items from a shortage report to a purchase order?

I am maybe doing this wrong so tell me if it is the case.

Thank you.