The Sequence ID has been introduced in BOMs which is a long awated feature.

However, it has not been fully thought through or not yet implemented fully. That is,

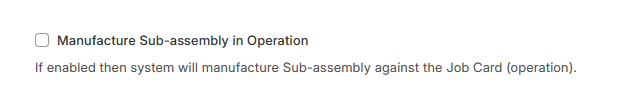

consider a multilevel BOM with subassemblies. It is possible that the operation is repeatedly used under different subassemblies. Consider the case where user selects Manufacture Sub-assembly in Operation to reduce the need for Work Order, Job Card execution.

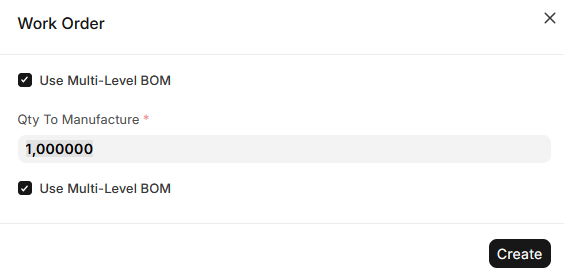

They may do it using a Multi level BOM (The capture below is with the last update which introduced another bug already)

In that case, the Work Order/Job Card will receive materials to be consumed on different subassemblies but the current version will gather them under the same Job Card for Operation and furthermore will create trouble in determining the order of operations.

Even though in cases on the same BOM, when the operation need to be addressed more than once, that will create a problem.

What you need to do in the code is:

- if the BOM has opeations,

- if the BOM Items have operation assignment, (in this case, the reference should be not the Operation name but rather BOM Operation Sequence ID)

- Work Order sequence need to be determined by the BOM structure, (where I think using the multi-level BOM is an idiotic approach)

- Job Cards need to be created not only by Operation name but subassembly name, subassembly BOM operation sequence ID and thus operation name.

In current state of the Manufacturing implementation, we are still ages behind leading ERP/MRP products in that sense.