Item A is a steel bar length in 18 feet if we sell in half or 5 feet how to manage inventory in bars

@NCP Sir, please guide me

I haven’t any idea about this type of scenario but I think you should make a length-wise item.

And I think also check the Item Variants functionality and create a template and added a length size in item attributes. Then create various length-wise Items from Item Template.

Thank You!

Hi:

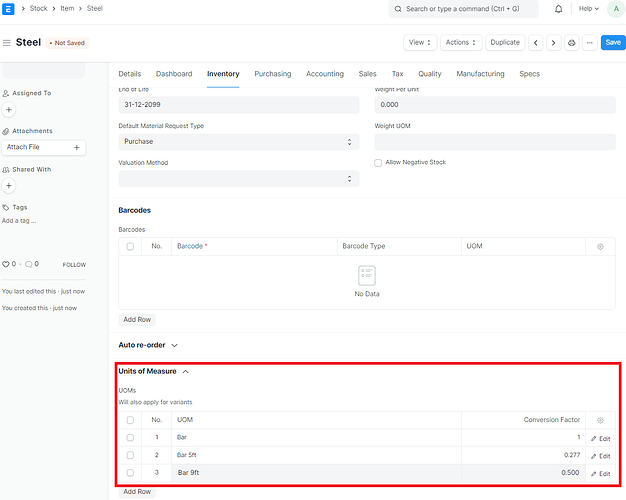

Other approach … use additional UOMs. Just one item, with different bar sizes.

Create ITEM Steel and set main UOM as Bar

This way, in buying and sales process you can choose UOM (bar, 5ft bar, 9ft bar …).

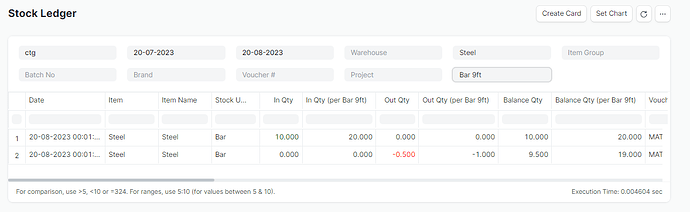

Stock ledger shows stock qty in main and secondaries UOMs

Hope this helps.

You may need to extend the logic to standard lengths kept in stock. on sale a cutlist will deduct the length sold with the remainder in stock with non-standard length

How to extend the logic? Please

Thanks sir, but if bar 9ft is sold, 18ft should be less one and 9ft should be plus two and less one in stock.

You could create two (virtual, reflecting the real situation) bins for stocking the bars:

- One bin for the uncut bars, where you just have a count for the stock.

- Another bin for the cut unsold bars. This bin will have another type of items where you have (or use) an additional attribute “length”.

The business logic is like this:

- When you take a bar to cut it and sell one part of it, you take one item from bin 1 of the stock, manufacture two items of (a) required length and (b) resting length.

- Registering: bin 1 has one item to be deducted, bin 2 has one item with resting length to be stocked in it, and one item of required length will be entered in the invoice.

You can perform this business logic manually, but of course some automatism will be useful if this happens regularly or often.

You could use two item types or just one with setting the attribute “length” as a default value when updating incoming items into your raw material bin 1, depending on your preference.

Yes, as @Colin_Tan says … it depends on the way you want to control this.

Strictly stock control for each bar size will require one item for each bar size (you can use variants) or customizing serial numbers with “Bar size”. Anyway, you will need a method to make the right stock entries.

Triggering the logic from sales process needs a pretty deep customization (launch stocks in/out, etc …)

This customization was made for ceramic tiles business.

Manufacturing process is other way (probably, the nearest to the real process). Sales order → Work order (with stock entries) → Delivery note

Hope this helps.