We Manufacture Item A and keep stock of item A.

So item A has a BOM to manufacture it.

we manufacture item B, THAT INCLUDES item A as an assembly.

How do we setup a BOM for item B so that item A GETS PULLED FROM STOCK?

WORK ORDERS for item B MANUFACTURES item A instead of pulling it from stock.

That is what a BOM is. Cascade it

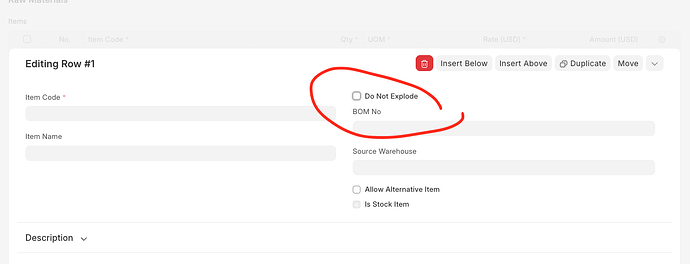

I’m not sure if this helps, but it seems like the “Do not explode” setting should help.

You may need to create two separate BOMs if you occasionally manufacture item ‘A’ when manufacturing item ‘B’. Or perhaps you can uncheck the box for that specific run.

For the BOM where you’ll pull item ‘A’ from inventory, you can check the box “Do not explode” when adding item ‘A’ to item ‘B’ BOM.

THANK YOU!

This is what i needed. Thank you

HELLO

This DO NOT EXPLODE function no longer works??

could you or anyone confirm if it is a new bug that creeped in or if the fault is by me?