here troubling you for a case, glue is not part of BOM, but if we don’t put glue in the BOM, during production, we need glue, but there is no glue prepared. cause downtime. is there a good solution better than putting glue in the BOM.

Hi,

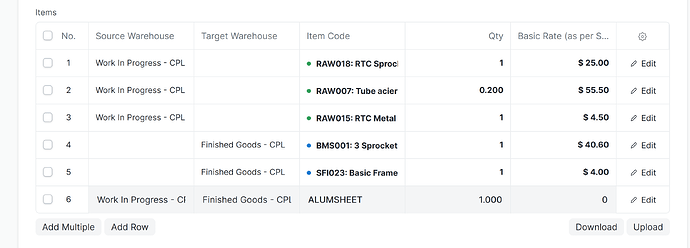

You can add the item, which is not in the BOM at the time of finishing the work order by clicking on add row and select the material you want to consume. In following screenshot, I added ALUMSHEET, which was not the part of the BOM.

Thanks,

Hi @RoyHu :

Consumables are categorized into 2 types.

- Process Consumables (Adhesives, Paint Materials, Glue etc )

- General Consumables (Cleaning solvents, cotton waste etc)

Step-1. Do not add consumables into BOM as they are consumed in fractions.

Step-2- Create Material request for consumables → Type - Material issue -->Select Proper “Project”–> collect materials from stores and keep it in production line.

Step-3 → use them as required qty as mentioned in the drawing or documents.

hope this helps

Prasad Naik

thank you all for the helps!

Dear @prasad_naik, it is really helpful, it is also bring me question like below?

where to category Consumables, does it in the item master, using item group to category them?

and who is responsible for creating material request? the production planner? who knows which product need gule. we made torch, some of them are need glue, some of them don’t, it is easy to miss bring glue to production, if not put the glue in the bom, seems it is best solution, but it is really should not put in the BOM.

Consumables needs to be categorized in item group level

Parent Item Group - Consumable

Sub Level Item Group-1- Process Consumable

Sub Level Item Group-2- General Consumable

- Production Planner is responsible for creating MR , Getting approved, take materials from inventory and issue to production

- Engineering document should call for which glue to be used (Not necessarily in BOM) (Example : Job card, SOP)

- Create BOM for all consumables at once and provide to Production planner with quantity per system consumption. they will take care of procurement , Minimum stock level and ordering as well

thanks

Dear @prasad_naik,

it is very nice to have your answers, it is what i need, you are really good,

do you mean a BOM pure for consumables? it is not even a product, just orgnize all consumables? i mean it open my eye, i think it is good solution, but who would create a BOM just for the usage in the production, who will know how much would consume in the production, i think it should be engineer, right?

i post an other topic about multi-level BOM, when produce them, it should be done by many workstations in different places, source WH and target WHs are also many, so when i create an work order for this BOM, all raw material are on one stock entry, i really need the stock entry are many based on workstations or warehouses. here is i posted: