Hi Ben,

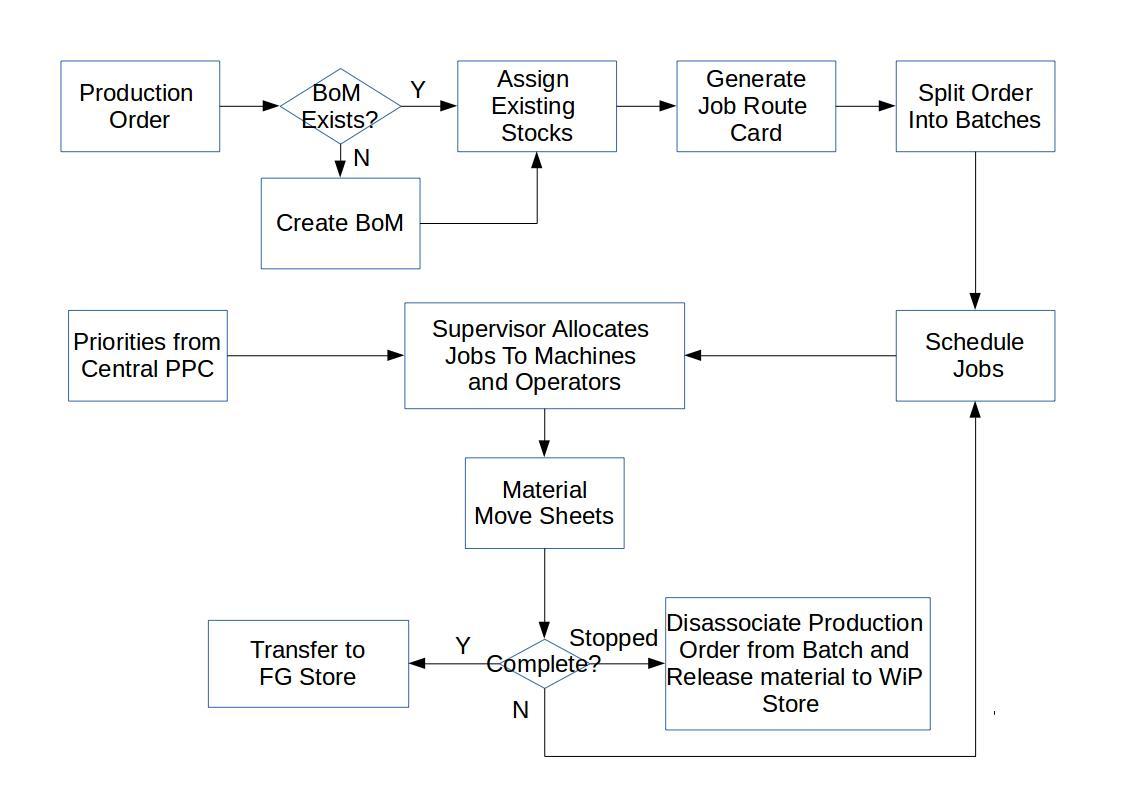

The assign stocks process is to put material on hold for a specific job. The material move sheets is the result of the material transfer for manufacture. Both from the raw material store to the shop floor and on the shop floor from one process/workstation/operation to the other.

I am assuming that some organizations will need to track on ERPNext every process/operation while others will only want to track only a few discrete points. This is specified in the BOM. But in addition one has to specify whether that process or step or operation needs to be tracked on ERPNext. Most organizations may only want to do end of the day/shift entries on ERPNext.

So a Job Route Card is a way by which the shop floor knows what processes/operations are complete and where next to send the WiP material to. I’m proposing that ERPNext generates the Job Route Card that gets tagged with the material and goes around on the shop floor. As a process/operation gets completed , the operator/supervisor makes the appropriate entries (as defined in the BOM) on the Job Route Card itself and sends the material onto the next process and location. The processes/operations where ERPNext needs to be entered is printed in bold or another color, so the operator/supervisor knows that s/he needs to update ERPNext about having completed that process/operation.

Let’s say you have a Product P that flow’s through the following processes:

RM>A>B>C>D>P

For simplicity’s sake let’s say that you want to track every process.

Let’s say you receive an order for 100 Nos of P and you already have the following in stock:

P - 20 Nos

D - 15 Nos

C - 10 Nos

B - 25 Nos

A - 5 Nos.

So when you run the Assign Stock process, all of these stocks get assigned to this Production Order and ERPNext generates the following Job Route Cards:

PROD12345-D-P-15: For converting D to P for 15 Nos.

PROD12345-C-P-10: For converting C to P for 10 Nos.

PROD12345-B-P-25: For converting B to P for 25 Nos.

PROD12345-D-P-15: For converting A to P for 5 Nos.

PROD12345-RM-P-25: For converting RM to P for 25 Nos.

Batches: Different machines and operations have different capacities. For instance, here A could be on a lathe that turns out one component every 10 minutes, whereas B could be on a Drilling machine that could turn out one component every 2 minutes. Plus there is dependence on the number of machines of each category. So if you want to make 20 components and you have 5 Machines, you may want to break this up into 5 Batches of 4 components each. So the ability to break it up into batches gives the production supervisor the flexibility to do this, while still ensuring that traceability of machines, operators, etc. can be maintained. Also most organizations will want to plan their production activities for a shift, half shift, 2 Hours etc. So the other function of the batch is to ensure that the batch fits the planning horizon (or time interval) of the batch.

Please let me know if I’m complicating things way too much.

Thanks

Jay